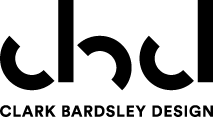

Herring is a family of furniture that is easily assembled without glue or fixings. The size and spacing of the interlocking fingers that form the basis and identity of the collection are derived from the 3/8” cutting tool that is standard on all CNC cutting machines. By expressing the join between panels, the products elevate a material with a low perceived value in to something beautiful and functional.

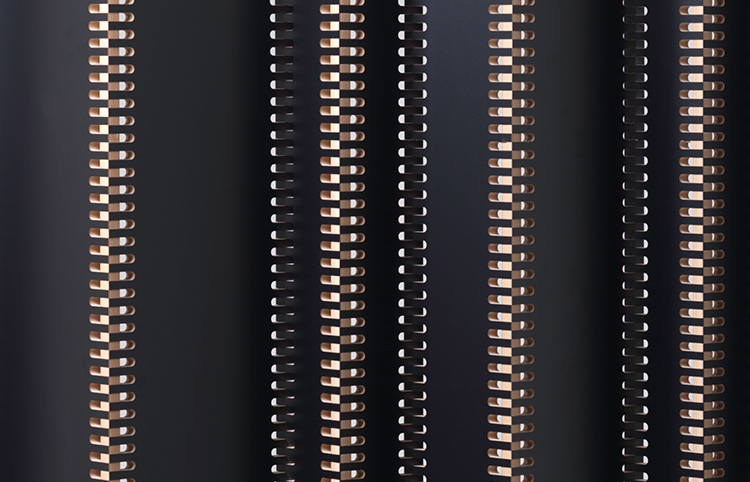

Instead of pulling material from waste bins, our approach was to intercept the material at a digital stage, before it became waste. We created the Herring designs to efficiently and automatically nest in to the waste areas of a sheet in any given job, minimally increasing cutting time, but dramatically increasing the value of that waste by turning it in to desirable and useful products.

The screen is designed to take advantage of the narrow lengths of waste common along the top edge of cabinetry cutting jobs. The crates are dimensioned to fit the still commonly found squarer proportioned off-cut areas.

Herring products come straight off the CNC machine and can be packaged as a product with minimal finishing, and without the addition of other parts. This helps ensure the value added is not at the expense of the CNC operators existing processes and operations.

This is part of a body of work created for Resource: Rise Again - a project by Christchurch based social enterprise Rekindle, supported by Creative New Zealand.

Waste MDF laminate

Photography by Cornelius Geraets

What we did

Material research

Concept Design

Prototyping

Design for Manufacture