Nine months of research and design have yielded a set of ideas made using waste from commercial CNC cutting of MDF laminates.

CNC cutting is a huge contributor to landfill. Around 20% of every sheet that is cut will become waste. That means around 17,500 cubic metres of MDF ends up in New Zealand dumps every year.

Instead of pulling material from waste bins, our approach was to intercept the material at a digital stage - before it became waste. We created the designs to efficiently and automatically nest in to the waste areas of a sheet in any given job, minimally increasing cutting time, but dramatically increasing the value of that waste by turning it in to desirable and useful products.

This is part of a body of work created in collaboration with Mitchener Architecture and Design for Resource: Rise Again - a project by Christchurch based social enterprise Rekindle, supported by Creative New Zealand.

This piece of work has been selected as a finalist in this year's Best Design Awards

Split products are decorative and acoustic wall tiles for commercial environments created by splitting and sealing MDF shapes cut from waste areas of sheet. The splitting exposes and celebrates the natural timber fibres that make up the sheets. Afterwards water based coloured stains are soaked in to the fibres to create an attractive, safe and durable finish. The process transforms beige MDF fibres (that we usually work so hard to conceal) in to bold, colourful, and unique wall tiles and panels that would otherwise be condemned to landfill.

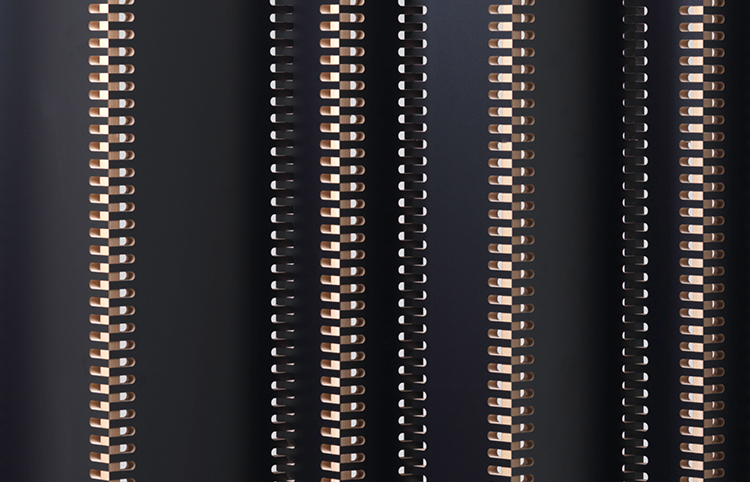

Herring is a family of furniture that is easily assembled without glue or fixings. The size and spacing of the interlocking fingers that form the basis and identity of the collection are derived from the 3/8” cutting tool that is standard on all CNC cutting machines. By expressing the join between panels, the products elevate a material with a low perceived value in to something beautiful and functional.

The screen is designed to take advantage of the narrow lengths of waste common along the top edge of cabinetry cutting jobs. The crates are dimensioned to fit the still commonly found squarer proportioned off-cut areas.

Herring products come straight off the CNC machine and can be packaged as a product with minimal finishing, and without the addition of other parts. This helps ensure the value added is not at the expense of the CNC operators existing processes and operations.